What is the water cooling principle of diesel generator sets?

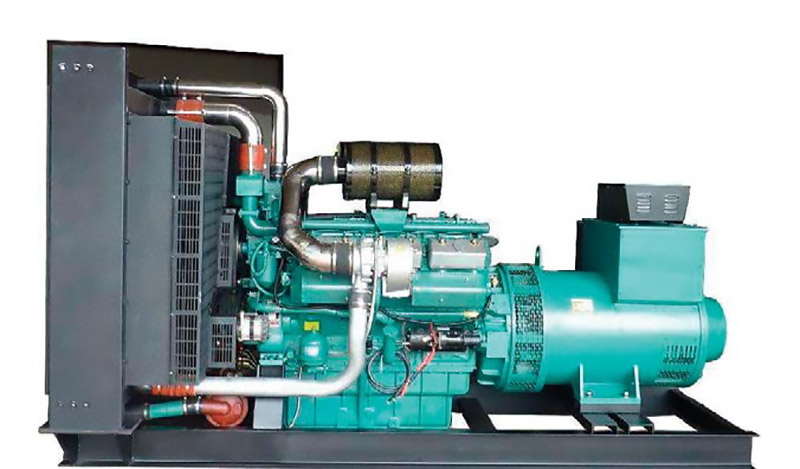

The diesel engine cylinder head and cylinder block are both cast with cooling water jackets. After being pressurized by the water pump, the coolant enters the cylinder water jacket through the water distribution pipe. While flowing, the coolant absorbs the heat from the cylinder wall, causing the temperature to rise. Then, it flows into the cylinder head water jacket and enters the radiator through the thermostat and radiator through the water pipe. At the same time, due to the rotation and suction of the fan, air blows through the radiator core, causing the heat of the coolant flowing through the radiator core to continuously dissipate into the atmosphere and reduce the temperature. Finally, after being pressurized by the water pump, it flows into the cylinder water jacket again, continuously circulating, and the diesel engine speed increases. In order to ensure uniform cooling of the front and rear cylinders of a multi cylinder diesel engine, a water distribution pipe or a cast water distribution chamber is generally installed in the cylinder block of the diesel engine. The water distribution pipe is a metal pipe with a longitudinal thermal water outlet, which is larger from the water pump. This can make the cooling intensity of the front and rear cylinders similar, and the overall cooling of the machine uniform.

The water cooling system is also equipped with a water temperature sensor and a water temperature gauge. The water temperature sensor is installed at the outlet pipe of the cylinder head and transmits the water temperature of the outlet pipe to the water temperature gauge. Operators can use the water temperature gauge to constantly understand the working condition of the cooling system, and the normal working water temperature is generally between 80-90 ℃. The coolant used in diesel engines should be clean soft water. If hard water is used, minerals in it will precipitate at high temperatures, adhere to pipes, water jackets, and radiator cores, forming scale, reducing heat dissipation capacity, making the diesel engine overheat, and also blocking the radiator core, accelerating the wear of the water pump impeller and pump casing. For hard water with high mineral content, it needs to undergo softening treatment before being added to the cooling system for use. The commonly used method for softening hard water is to add 0.5-1.5g of sodium carbonate or 0.5-0.8g of sodium hydroxide to 1L of water. After the generated impurities precipitate, clean water from above is taken and injected into the cooling system.

Guangzhou Saiwei Energy Technology Co., Ltd. is a comprehensive enterprise specializing in the design, production, and installation of generators. Guangzhou Saiwei has many years of experience in engineering design and installation services. For many years, Guangzhou Saiwei has been committed to providing every customer with comprehensive products and energy solutions, including technical consulting, whole machine and generator supply, operation training, etc., with leading technology and first-class quality. The product range covers land diesel generator sets, marine generator sets, high-voltage generator sets, etc., and is widely used in industries such as power, communication, iron towers, healthcare, financial systems, data centers, etc. Welcome to inquire: 13302262088

- More information